The recycling of agricultural and packaging films is a difficult task. Because agricultural films usually have extremely high levels of mineral and organic impurities, the films themselves are thin and soft, ranging from 25 μm to 100 μm thick. These very thin films are extremely difficult to break, separate or clean. On the other hand, the film is made up of high quality plastics such as LDPE and LLDPE, which are highly sought after in the recycled pellet market, and high quality recycled pellets are expensive, making them highly valuable for recycling.

The entire production process is briefly described as follows: First, rough impurities such as wood, stone, mud and metal are sorted, as well as other plastics from the agricultural sector, such as string or net. After the film has passed through several shredding, cleaning and drying cycles, it is left with material that can be fed to the extrusion screw for pelletizing. The final recycled pellets are sold to film manufacturers for use in the manufacture of different products such as garbage bags, or for re-production of agricultural films.

Batte offers better solutions according to the characteristics of agricultural and packaging film recycling, production principles, common materials, process characteristics, heating temperatures, processing pressures, production volumes, etc.

Materials produced: agricultural film, packaging film, plastic bags

Process characteristics: high yield, high material impurity content, high temperature, high viscosity, low pressure fluctuations, high stability and reliability requirements

Heating temperature: 200~280 ℃

Heating pressure: 7.0-20.0 MPa

Output: 30-2600 kg/hr

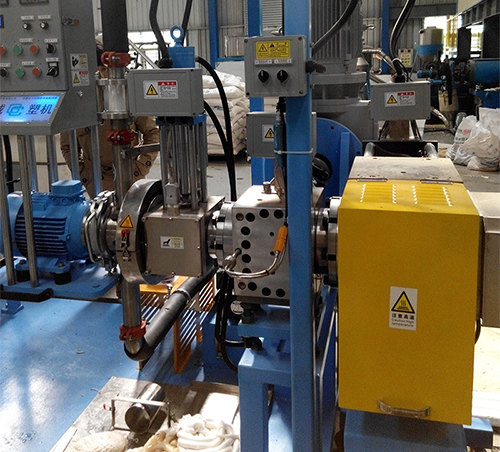

Batte product solution: recycling granulation melt pump + single plate screen changer / double column screen changer / backwashing screen changer

Twin-screw extruder and melt pump combination of blending extrusion pelletizing production line, the use of melt pump can effectively reduce the twin-screw extruder own pressure building function, improve the twin-screw extruder production efficiency (twin-screw machine own pressure building function is poor, seriously affect the production efficiency). For twin-screw machine combined with melt pump and pipe, plate, film and other extrusion head into a production line, it has the advantage of pressure building, it can also achieve energy saving by simplifying the process of extrusion products production process and shortening the production cycle. Using twin-screw machine + melt pump configuration, it is particularly suitable for extruded products of materials need to be co-mingled and modified; materials must be mixed and homogenized through the allowable points to achieve product quality requirements.

Recycling pelletizing raw materials in very many impurities, changing the net frequently, requiring a large filtering area, so the use of large specifications of the plate screen changer and column screen changer, the cost is relatively not high, and the commonly used manual, electric screen changer in production, quality can not meet the requirements, and no net slagging type screen changer, no need to change the net, automatic slagging, and can reach the slagging continuous production, so the majority of the pelletizing industry Therefore, it is favored by the majority of friends in the pelletizing industry. The main limitation of the netless slag filter is that the filtering precision of the net plate is only 70 mesh, and the service life of the net plate can produce several hundred tons of pellets. However, the screenless slag filter is adapted to the requirements of pelletizing conditions and fills the application gap of the plate screen changer, column screen changer and mesh belt screen changer, which is a very suitable screen changer for recycling pelletizing production.

Batte, as a professional screen changer manufacturer in Zhengzhou, has many years of experience in the development and production of screen changer filters (screen changer is also called screen changer filter); providing special screen changer equipment including: automatic screen changer for plastic pelletizing machine, screen changer for extruder pelletizer, screen changer for waste plastic recycling and pelletizing, etc., which is indispensable equipment in the current plastic recycling and pelletizing industry.

Modified pelletizing raw materials have less impurities and higher value of raw materials, in the choice of screen changer, generally choose double column double-station screen changer for pulling production, to achieve the purpose of changing the screen without stripping; for hot cutting, underwater cutting and other ways to use the more cost-effective single-plate double-station screen changer.

Soft PVC and other easy-to-age raw materials for pelletizing, to choose the runner straight, no dead ends, no stagnation of the screen changer, and single-plate duplex screen changer is very suitable for a screen changer, is also the only available screen changer. Similar to the production of soft PVC and other easy-to-age raw materials, the single-plate duplex screen changer should be modified and upgraded in the original structure, and use different processing technology to achieve the corresponding production requirements.

The screen changer is used in plastic recycling pelletizing operations to filter impurities in the melt and provide a clean and impurity-free melt for subsequent processes to ensure the quality of the finished product. Zhengzhou Batte screen changer is a double-column, double-station screen changer, which is designed with double channels and double screens, the function of which is to change the screen when one screen is working and one screen is being replaced, so as to achieve uninterrupted material flow without stopping to change the screen; the screen changer is designed with an exhaust system, the purpose of which is: it can fully exclude the gas trapped in the melt and the porous plate to be changed, so as to prevent the formation of gas in the final product and affect the quality of the product. It has a large filtering area and strong production capacity, with an output of 30kg/h-2600kg/hr, which can meet the needs of large plastic pelletizing production line; the plastic pelletizing screen changer adopts rigid sealing to extend the service life and other advantages.

The specific choice of which melt pump and screen changer also need to be selected according to the working conditions, materials and parameters of the production line, welcome to consult. info@battemachinery.com